The project ‘Expansion of the scope of work of the prototyping laboratory for optoelectronics, mechatronics and physics solutions’, funded by the Innovation Incubator 4.0′, coordinated by CTT UG, has come to an end.

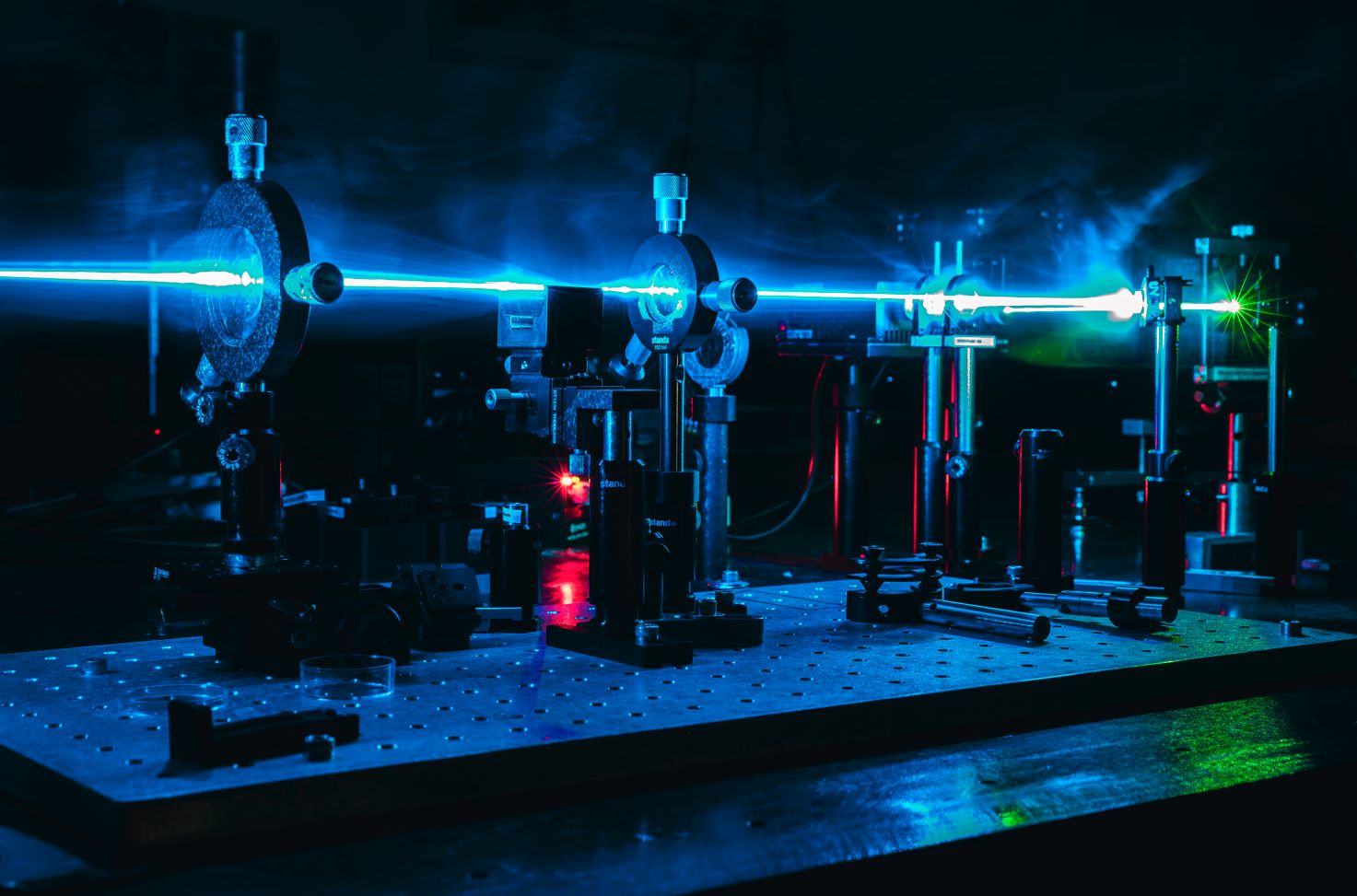

A team of researchers from the Institute of Experimental Physics of the WMFiI, under the direction of Sebastian Mahlik, Ph.D., Prof. UG. has expanded the existing laboratory infrastructure to enable additional work to be carried out in the Prototyping Laboratory. The laboratory specialises in research in industrial optics or ageing processes, as well as in the prototyping of electronic devices, especially lighting devices. The newly created test benches, make it possible to carry out customised work for industrial partners.

As part of the project, the following were extended:

– a station for soldering electronic components with a soldering oven, soldering stations, a microscope and a stencil printer for solder paste. Thanks to the extension, the possibilities of manual soldering of electronic components have increased significantly (from component size 0603 to 0402), and the quality and repeatability of soldering connections have improved.

– infrared luminescence decay time measurement station with an oscilloscope, function generator and fibre optic spectrometer. The expansion expanded the available spectral and measurement time ranges, improved the quality of the measurements and reduced the measurement time.

– a stand for measuring the spatial distribution of illuminance for illuminators from ultraviolet to near-infrared with a maximum size of 30x30cm. This bench makes it possible to verify the characteristics of designed and commercially available light sources.

– LED packaging station (applying phosphor to blue InGaN modules). The bench makes it possible to create prototype light emitters with individual spectral characteristics.

– a state-of-the-art microplate illuminator kit was developed for applications including biotechnology, biology and chemistry measurements. This illuminator is characterised by a high optical power density (over 100mW/cm2) and high expandability.

Project activities have led to collaborations with companies that use the laboratory’s services for prototyping, development of new technological solutions and innovation.

In this respect, cooperation with Lenta Sp. z o.o. was extended, with preliminary spectroscopic and microscopic studies of aged materials.

With the expansion of the infrastructure, the creation of new measurement systems and a flexible approach to design, the laboratory is now able to offer more advanced research services, contributing to closer collaboration with industry. The project is an important contribution to the development of scientific research and technological innovation at the University of Gdansk.